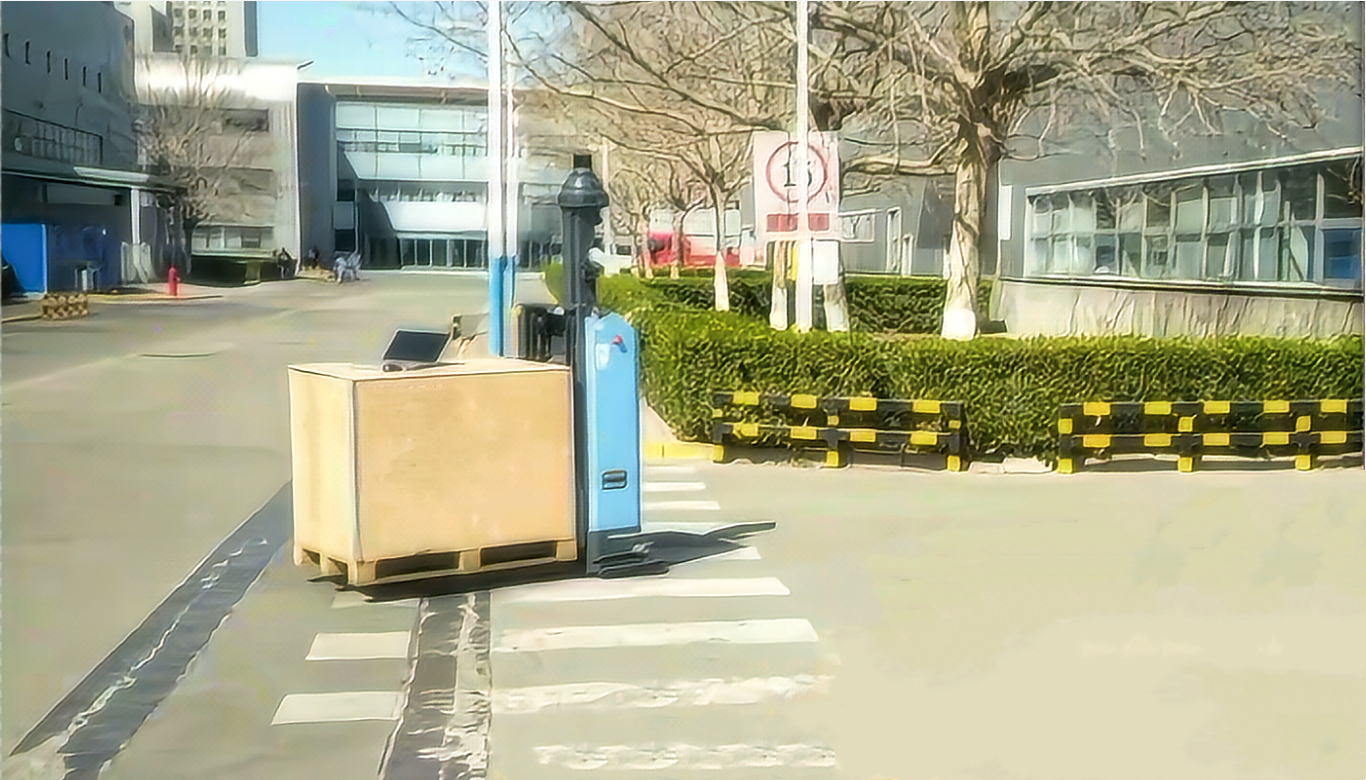

It can drill into the rack for jacking and handling, with a maximum load of 800kg;

the repeatability is as high as ± 5mm; Wi-Fi roaming is supported to achieve more robustness network data interaction;

trackless laser SLAM navigation, with multi-sensors such as 3D obstacle avoidance cameras for safety protection;

jacking robots can realize flexible handling of goods between designated locations,

such as e-commerce sorting, material transfer, call feeding, etc.

link, liberate manpower and realize unmanned transportation.

Based on the SRC controller, combined with SEER software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

An astonishing accuracy of ±5mm matches the general positioning demands of various scenarios.

Worry-Free Battery Life: up to 12 hours for uninterrrupted operation.

The modular design guarantees unparalleled reliability and stability and the maintenance becomes a breeze, enabling you to save significantly both time and money.

Based on the SRC controller, combined with SEER software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

An astonishing accuracy of ±5mm matches the general positioning demands of various scenarios.

Worry-Free Battery Life: up to 12 hours for uninterrrupted operation.

The modular design guarantees unparalleled reliability and stability and the maintenance becomes a breeze, enabling you to save significantly both time and money.

Based on the SRC controller, combined with SEER software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

An astonishing accuracy of ±5mm matches the general positioning demands of various scenarios.

Worry-Free Battery Life: up to 12 hours for uninterrrupted operation.

The modular design guarantees unparalleled reliability and stability and the maintenance becomes a breeze, enabling you to save significantly both time and money.

Based on the SRC controller, combined with SEER software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

An astonishing accuracy of ±5mm matches the general positioning demands of various scenarios.

Worry-Free Battery Life: up to 12 hours for uninterrrupted operation.

The modular design guarantees unparalleled reliability and stability and the maintenance becomes a breeze, enabling you to save significantly both time and money.

Based on the SRC controller, combined with SEER software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

An astonishing accuracy of ±5mm matches the general positioning demands of various scenarios.

Worry-Free Battery Life: up to 12 hours for uninterrrupted operation.

The modular design guarantees unparalleled reliability and stability and the maintenance becomes a breeze, enabling you to save significantly both time and money.

| Product model | |

|---|---|

| Product model | AMB-300JZ |

| Basic parameters | |

|---|---|

| Product name | Laser SLAM Lifting Robot |

| Navigation type | Laser SLAM |

| L x W x H | 792 x 580 x 250 mm |

| Rotation diameter | 910 mm |

| Weight (with battery) | 150 kg |

| Maximum load capacity | 300 kg |

| Chassis ground clearance | 25 mm |

| Lifting platform dimensions | 760 x 545 mm |

| Maximum lifting height | 60±2 mm |

| Navigation laser scanning height | 188 mm (H1) |

| Ambient temperature and humidity range | TEMP: 0°C to 50°C / RH: 10% to 90%, no compression, no condensation |

| Performance parameters | |

|---|---|

| Passability (slope / step / gap) | ≤5% / 5 mm / 30 mm |

| Minimum aisle width | 640 mm |

| Navigation position accuracy | ±5 mm |

| Navigation angle accuracy | ±0.5° |

| Driving speed | ≤1.5 m/s |

| Battery parameters | |

|---|---|

| Battery specifications | 48 V / 20 Ah (lithium iron phosphate) |

| Comprehensive battery life | 8 h |

| Charging time (10% to 80%) | ≤1 h |

| Charging method | ≤1H |

| Charging method | Manual / Automatic / Fast battery swap |

| Configurations | |

|---|---|

| Lidar number | 1 (H1) +1 (C2) |

| E-stop button | ● |

| Speaker | ● |

| Ambient lamp | ● |

| Bumper strip | ● |

| Function configurations | |

|---|---|

| Basic functions | ● |

| Wi-Fi roaming | ● |

| Automatic charging | ● |

| Shelf recognition | ● |

| Precise positioning with QR code | ○ |

| QR code navigation | ○ |

| Laser reflector navigation | ○ |

OF 3C ELECTRONIC MANUFACTURING PRODUCTION LINE

and because the cooperation of various production lines and handling is carried out in the form of manpower + magnetic stripe carts, coupled with the system of working on two

sides and difficult-to-handle materials, many companies face high labor costs and low handling efficiency. As the industry-leading lighthouse factory,

it is looking for a smarter and more flexible circulation form of the production line.

Recently, the Chuzhou HKC mobile robot project, the leader of panel manufacturing service of SEER Robotics, was officially put into use in the workshop, helping it to build an intelligent logistics workshop, maximize the efficiency of cargo transfer, and provide strong support for the whole process business of the production line.

One fortune 500 company in France. Pro-face is one of the 90 "lighthouse factories" in the world. Due to the large production workshop area and scattered production vehicles, and because the cooperation of various production lines and handling is carried out in the form of manpower + magnetic stripe carts, coupled with the system of working on two sides and difficult-to-handle materials, many companies face high labor costs and low handling efficiency. As the industry-leading lighthouse factory, it is looking for a smarter and more flexible circulation form of the production line.

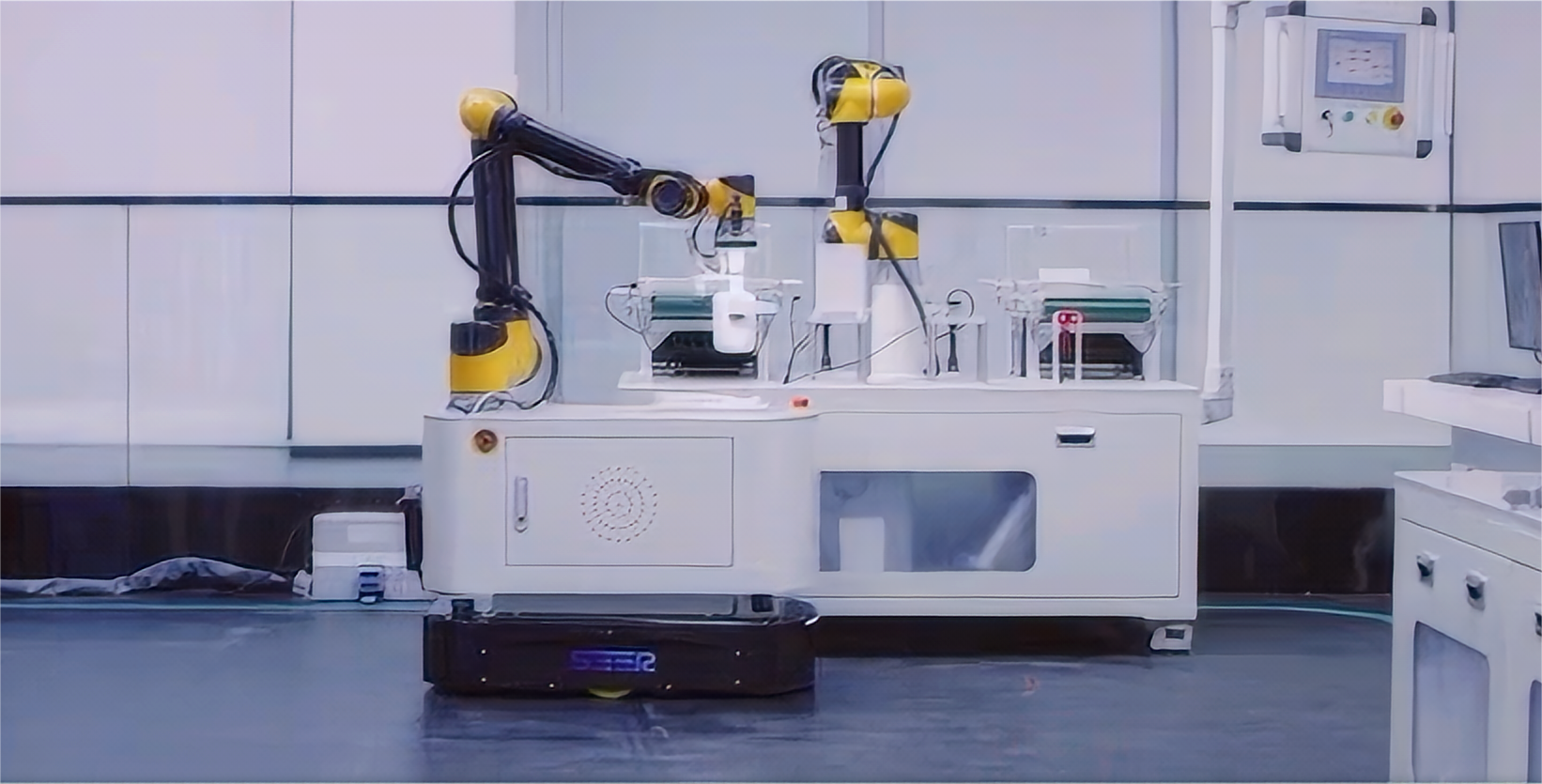

SEER Robotics and Jicui Intelligent Manufacturing have joined forces to create the Siemens Industrial Innovation Center exhibition hall, which is used to display siemens intelligent audio, driving recorders and other products.

The customer coming on the scene is mainly engaged in the production, manufacturing, research, development and application of high-voltage variable-frequency drives, with a plant area of over 5,500 square meters and a footprint of about 15,000 square meters. Owning strong technical force, the customer is committed to providing high-quality high voltage variable frequency drives, and delivering varied applications as well as comprehensive & complete services.

After a detailed comparison of the mobile robot navigation method, robot performance and the whole solution through various inspections, a SEER Robotics integraend-to-end industrial logistics solutionstor finally won the bid for the internal logistics automation transformation project of the factory floor. The successful implementation of this project not only realizes the automation and intelligence of the workshop logistics, but also greatly reduces the personnel input and saves a lot of labor costs for the enterprise.